Bevels, Hole, and Notch Quality Standards

Bevels

-

Based on machine capabilities

-

Bevel width tolerance is +/- 3/32"

-

Bevel corner tolerance on 1 1/4" and above is +/- 3/16"

Holes

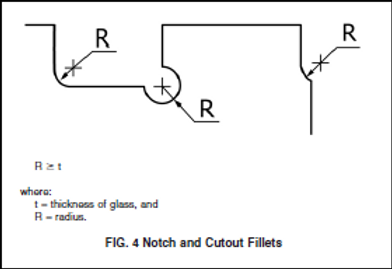

Location (See Figure 1):

-

Minimum distance from edge of glass: 6 mm (1/4") or 2x glass thickness, whichever is greater.

-

Minimum distance between holes: 10 mm (3/8") or 2x glass thickness, whichever is greater.

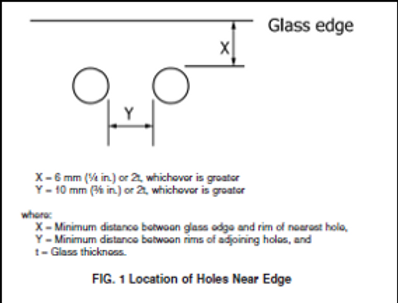

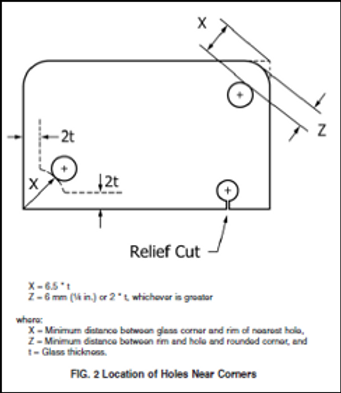

Location (See Figure 2-3):

-

Minimum diameter of circular holes: 6 mm (1/4") or the thickness of the glass, whichever is greater.

-

Any other holes: Required to have fillets. Fillet radius must be equal to or greater than the glass thickness.

-

Hole Dimensional Tolerance: ± 1.6 mm (1/16")

Notch

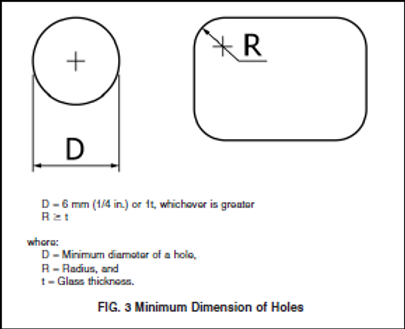

Location (See Figure 4):

Notch & Cutout Dimensional tolerance:

-

± 1.6 mm (1/16") for glass thickness less than 1/2"

-

± 3 mm (1/8") for glass thickness 1/2" or greater