top of page

Inspecting Glass for Quality Issues

-

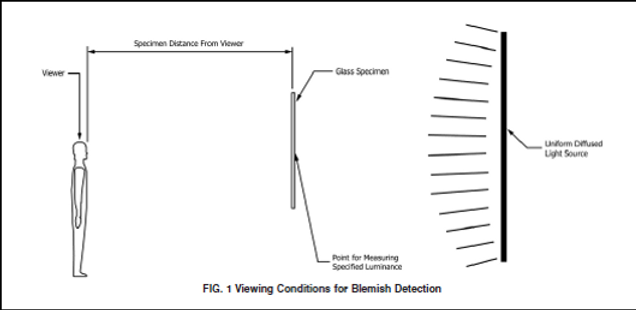

All visual inspections shall be made with 20/20 vision.

-

View glass at 90° in daylight, but not direct sunlight.

-

Stand at distance as specified by type of defect, focusing on the central area (center 80% of length and width) while looking through the glass and not directly at the surface.

-

For chips: View chips from 1' away without magnification, using localized lighting.

Visual Standards - Bowing

-

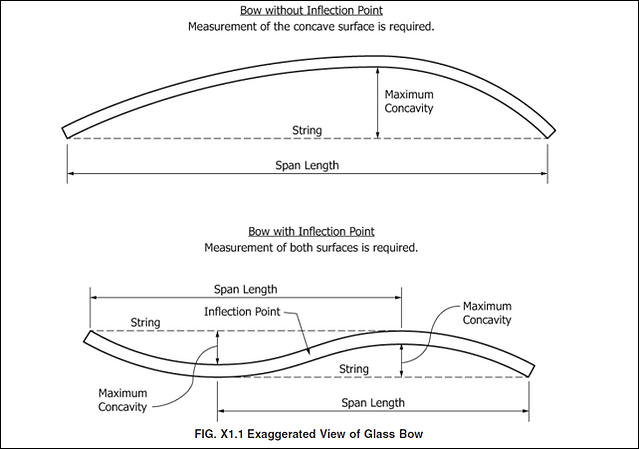

Use a "true straight edge, wire, string or monofilament fishing line."

-

Measure each of the 4 sides for overall bow on the concave portion of the glass within 1" of the glass edge and parallel to the edge.

-

Also check the approximate horizontal and vertical centerlines for overall bow.

bottom of page